Kenny Brown Chassis Reinforcement

The chassis is always the place to begin when making platform

modifications. Take care

of chassis reinforcement first. Before changing the suspension and before adding

significant power. If you reinforce

the unibody first to create a rigid structure prior to moving on to other areas, you won't

risk chassis fatigue when stiffening the suspension, and you won't twist

the unibody by applying too much torque to a stock platform. You'll also avoid being later surprised

that your suspension tweaks no longer work so well after you finally get

around to reinforcing your vehicle's structure because you postponed the chassis

work too long. Your vehicle's suspension needs will change as its chassis

dynamics are upgraded, so you could very well end up unnecessarily repeating

some suspension modifications if you don't proceed in the correct order.

With this in mind, I began investigating available chassis upgrades

soon after I bought Taz. Any convertible based on a coupe platform is prone to chassis

flex and cowl shake. Taz wasn't as bad as some old tin I've driven, but he was still

somewhat of a flexi-flyer over broken and

uneven pavement. Many have lamented the fact that all Mustangs from the Fox

bodies through the Terminators were based on the underpinnings for the old

Fairmont. Personally, I have never considered this such a terrible shortcoming.

But then, I

suppose I am one of a very few who still remember that the automotive press

acclaimed the Fairmont's rigid structure when it debuted, labeling the car the

"American Volvo." Indeed, the "lowly" Fairmont chassis was never considered

lowly at all, and the numerous tweaks that have been applied to the design over the years have

further strengthened the platform. Nevertheless, it was obvious that there was still room for

improvement, particularly with respect to the convertibles, since the Fairmont platform hadn't

been designed with a ragtop model in mind.

After considerable research, I settled on chassis components from

Kenny Brown. I opted for the full

Extreme

Matrix chassis reinforcement system, which stiffens the SN95 unibody structure by adding a

"mini-frame" of box-section and tubular steel, rather than by simply reinforcing the floorpan

longitudinally, as standard subframe connectors do. Unlike ordinary SFC's, even those constructed with seat

brackets, the Extreme Matrix vastly improves the chassis' torsional rigidity in addition to reinforcing

the unibody against longitudinal flexing. This helps to minimize the car's yaw tendencies, which cannot be

addressed with standard SFC's.

The advantage of adding lateral, as well as longitudinal, reinforcement

can be demonstrated by computer simulation, and using CAD/CAE software from AutoDesk, I confirmed that adding the Kenny

Brown Extreme Matrix to Taz's chassis would result in a 132% percent improvement in

chassis torsional rigidity, whereas SFC's alone would provide essentially no increase in

torsional resistance. Obviously, a matrix system would be less crucial for a coupe, because

its roof shell moderates its torsional deformation to a large extent. But a convertible's

platform cannot be adequately stabilized without some sort of matrix reinforcement.

Editorial Comment:

Why not a through-the-floor chassis reinforcement system? Well, because

Taz is a STREET CAR, not a dedicated track car. Furthermore, if I had wanted a 2-seater, I'd

have bought one to begin with. I wasn't interested in compromising the Cobra's ability to carry

rear passengers or in making the front seat area a less hospitable place to be. While there are a

few for whom these considerations are irrelevant, I believe the vast majority of folks will

agree with me on this one.

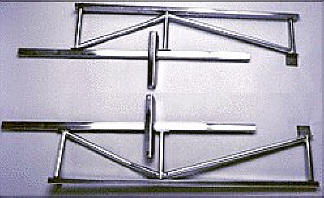

I had the Extreme Matrix components welded in by my regular body

and frame shop, and I stayed at the shop with the car until the chassis tech had finished

his work, so I can assure you this is a full 6-hour job when done right, even

for an experienced technician. Naturally, I neglected to shoot any pics of the

installation in progress, but here is a Kenny Brown stock photo of the

Extreme Matrix to provide a visual of the system's components.

Although the installation of this framework effectively negated the weight savings that I

had accomplished by swapping to lightweight BBS wheels, this weight was at

least confined to an area where it would impose the least negative impact. In

fact, the Kenny Brown pieces even help to lower the car's center of gravity

just a little.

NOTE: In

2005, Kenny Brown Performance, a leader in Mustang chassis and suspension

technology, temporarily ceased operations as a business entity after the

company's namesake fell seriously ill. That's the bad news. The good news is

that Kenny has fought his way back along a bumpy road to recovery, and KBP

products are once again available in the marketplace. A limited KBP product

selection can be found at the company's online store, as well as at a few select

vendors.

Editorial Comment:

There's an old adage that advises you can work harder or

you can work smarter, but the two are not the same. The chassis reinforcement

corollary to this adage is that you can stiffen a platform intelligently or you

can just keep throwing material at it until you achieve the rigidity you want. Knuckle

draggers invariably subscribe to the latter approach. These misguided souls refuse to even

consider the notion that anything as light as the Kenny Brown Extreme

Matrix system (about 40 lbs total) might be as effective as competing

products weighing much more. They contend that the Extreme

Matrix can't possibly do a proper job of shoring up the SN95 chassis because it

just isn't massive enough. This is not at all surprising, considering the majority of these

individuals aren't capable of even spelling finite element analysis, much less

grasping the concept.

OEM Convertible K-member Brace

All New Edge Cobra drop-tops left the factory equipped with bolt-on

front K-member braces to minimize cowl shake. Unfortunately, while hot-footing it

along a dark and twisty canyon road one night, I ran up over a fair sized chunk of

granite that had tumbled into the middle of the road during a rock slide and bent

Taz's brace. Luckily, the rock damaged only the brace, and the damage appeared

entirely superficial, but it still bothered me, so I replaced the part with a new

one while I had the car in the air for Taz's 6-speed transmission installation.

Below, you can see both the damaged original part and the replacement.

My thanks to Ford for adding this part to all ragtop Cobras. Not

only does it work well at keeping cowl shake in check, but it's entirely possible the brace

saved my motor that night. The large dented and scraped area that you see on the original

part had been located directly below the oil pan, so the brace took the hit in lieu of the

pan, itself. If the brace hadn't been there, the evening might have ended very differently

and most unhappily for me. Holing an oil pan on a desolate canyon road in the middle of the

night doesn't appear anywhere on my "must-do" list.

Editorial Comment:

Replacing the factory K-member of a New Edge ragtop with one of the

various aftermarket offerings would also require disposing of this brace. It appears to me

that if you do this, you'll be shooting yourself in the foot from a handling standpoint if

you are a corner carver. Just a little something to think about before you start "improving"

things in that area.

I realize that replacing one part with another identical part certainly

doesn't qualify as any sort of upgrade, but I thought I'd give the coupe owners a peek

at this convertible-specific part. A couple of my friends have asked if I thought they

could install these braces on their coupes. The answer to that question is that all things

are possible, but I think retrofitting one of these to a New Edge coupe might require a

disproportionate amount of time and effort. The coupes aren't equipped with the necessary

attachment points. Many of the dozen or so bolts that secure this piece are threaded into

proprietary weldments in the ragtop's unibody structure.

NOTE:

The above part is a BRACE. I've seen various Internet ignoramuses from time to time attacking

this part as - in their opinions - an inferior factory subframe connector because it bolts on.

First, it isn't a subframe connector at all. It's a K-member brace designed specifically to

reduce cowl shake on the ragtops. That's why it wasn't supplied on the coupes. Second, ALL

K-member braces bolt on, because they must be removable. Third, this part isn't inferior at

all. It's beefier than any of the aftermarket braces I've seen, and is secured by no less

than 13 bolts vs. two or four for most aftermarket pieces.

Suspension Upgrades, Round 1

One automotive modification invariably begs another, doesn't it? In my case, as soon as

the Cobra's chassis reinforcement was installed, the car began to feel under-damped and under-sprung. The

stock suspension components simply weren't up to the task of properly controlling the vehicle's ride motions

once the chassis flexing had been minimized, so I immediately began looking into suspension upgrades. I

didn't want to take Taz too far into the realm of hardcore handling, since he was primarily a street-driven

fun machine. Having heard many complaints such as, "I expected a rougher

ride after the install but right now I don't even want to drive it" (an actual quote from

a member of one of the Internet's Mustang forums), I was mindful of avoiding the introduction of undue ride

harshness with respect to the car's suspension upgrades. Just a few minor tweaks to sharpen its reflexes.

And since the stock suspension's ride height gave the car a bizarre 4WD appearance, I decided to lower it

a bit, as well as address its handling.

After considering my options, I settled on a set of Sport Springs from the German

manufacturer H&R. All performance springs

will lower a car to some extent, and the H&R's provided a moderate 1.5" drop all the way

around. I would have preferred less drop, but all the springs available at the time that offered less were

either a bit too stiff for my preference (e.g. '00 Cobra R springs) or a little too soft (e.g. the Steeda

Sport springs).

The H&R Sport Springs are progressive up front (700 - 760 lbs/in) and linear out back at 685 lbs/in,

which made for a decent ride on less than perfect public roads. Although these rates are stiffer than those of the

car's stock springs, which had been 500 lb/in in front and 470 in the rear, the progressive fronts did a great job

of mitigating the increased bump harshness. (All four of the OEM Cobra springs had been linear rate.)

Editorial Comment:

Why not shoot for a bigger drop? Well, from a performance standpoint, there are multiple

reasons to avoid lowering an SN95 Mustang more than installing a set of H&R's will accomplish. Lowering a

car too much ruins its handling ability, destroys its steering response, and subjects its undercarriage and exhaust

components to terminal road rash. Why would anyone want to alter a performance car in such a way that that it would

henceforth need to be eased around like Granny's LTD? Why not just buy an LTD in the first place and slam that, so

real car guys wouldn't want to rip your lungs out? And let's not even consider the possibility of removing all of

the vehicle's spring isolators to achieve an even more exaggerated drop, because that represents a level of stupidity

beyond words. Furthermore, from a purely visual perspective, any car lowered beyond a certain point looks completely

ridiculous.

Let's face it. Slamming a vehicle is just plain ignorant from any

standpoint, and anybody who does so merely to make his ride look "dope" is a moron who should be

sterilized in an effort to help clean up the gene pool. Yo! Home Boy! A vehicle is a dynamic entity. As such, its

intrinsic value is grounded primarily in how well it goes, turns, and stops. Modifications performed to any vehicle

that undermine those dynamic capabilities are simply retarded, regardless of the motivation. With all things

automotive, form follows FUNCTION! Besides, when your car's undercarriage is banging and scraping all over the

pavement, it doesn't look dope, just DOPEY - and so do you.

Because the rear H&R springs are wound with a number of

"dead" coils at their tops, many mistakenly believe that they are progressive, just

like the fronts. This is not so. Once the suspension is loaded, the dead coils

all collapse together, so they do not contribute to the springs' operation.

Below is a photo of a stock rear spring next to its H&R counterpart :

NOTE: A few years after installing

the H&R's, I became a road course junkie. This resulted in my eventually swapping out my Sport

Springs for a set of Engineered Performance (a.k.a. Kenny Brown Performance) springs

in a quest to move Taz toward more track-oriented handling. Refer to the section below detailing the

Cobra's 2006 - 2007 suspension modifications for comments regarding the swap.

Editorial Comment:

Have you been toying with the notion of going the economy route and

lowering your car by simply cutting your stock springs? Want to show a glimmer of intelligence by learning

from someone else's mistake for a change? Here is what one intrepid soul had to say about his

own results after cutting his factory springs:

"I cut 1 coil all the way around and this POS

drags everywhere. Plus it handles like ass. It was much better before. Cutting springs is a cheap

but wrong way to do a suspension. I will be changing mine in the near future. That's how much I

dislike it!!!"

Yes, that was a real assessment by an individual who

already made the mistake you may be considering. I don't invent these comments. I don't need to.

However, if risking the possibility of ending up the way that guy did just to save a few bucks when

lowering your car still sounds like the hot ticket to you, then have at it. I'm sure you'll get

exactly what you deserve.

For optimum performance, a vehicle's dampers must be matched to its

springs, so I replaced the stock units when I installed the H&R spring set.

I opted for Bilstein

shocks and struts valved to match the new spring rates. The Bilstein shocks

best matching the jounce and rebound characteristics of the rear Sport Springs

turned out to be the same shocks used on the 2000 Cobra R, and the struts that most

closely matched my new front springs were available at the time as P/N V36-4138-H1.

However, Bilstein revised its lineup shortly afterward, eliminating this strut

in the process and opening gaps in its product range. These gaps were later filled

during a subsequent revision, and struts comparable to mine were again made available as P/N

35-045939. Also, I do not believe the 2000

Cobra R shocks are available any longer. The closest substitute for those in the

current Bilstein lineup would be P/N

24-185974 (previously # F4-BE5-C265-H0).

As every owner of an SN95 Mustang knows - or should know - the factory strut

plates are marginal with regard to adjustability, even with the stock suspension geometry, and

their off-center 3-point attachment isn't as stout as it could be. Good caster/camber plates

were definitely in order. The

Maximum Motorsports C/C plates had been the de facto standard for some time when I went

looking for a set for Taz, and who was I to argue with success? The addition of a 4th baseplate

mounting stud to more evenly distribute the load on the strut tower meant drilling another hole

in each tower, but a man's got to do what a man's got to do. Below, you can see the new passenger

side C/C plate installed on the right strut tower:

Because these C/C plates employ Heim joints to locate the strut

shafts, they improve the car's directional stability at the price of a little

more NVH transmitted up into the chassis. Some individuals on the various

automotive forums will attempt to convince you that this is not true, and that

this design doesn't increase NVH at all. Do NOT believe them! Even

Maximum Motorsports will admit otherwise, as evidenced by the following

quote, which I lifted directly from the MM FAQ page for this product:

"The Caster/Camber plates themselves do not cause any

noise. However, they can transmit other suspension noises more easily than the

rubber factory strut mount. There may be a slight increase in road noise from

the tires, and slightly increased noise from the brakes. A slight increase in

harshness when encountering abrupt bumps may be noted."

While it is true that the NVH increase is slight, the increase

is discernable to those who are sensitive to such things. If you are

such a person, as I am, you will hear and feel the difference. I

have personally been willing to accept this minor NVH increase in order to

achieve more precise handling, but everyone is different, so you must decide for

yourself if this tradeoff will be acceptable to you. There are other C/C plates

available that provide the adjustability of the MM plates without introducing

more NVH, but they will not sharpen your car's handling. The choice is yours.

One of my axioms is that all things automotive involve tradeoffs. You'll see

this motto cited again and again throughout this site. Believe it. No truer

words were ever spoken with regard to our personal conveyances.

Reducing a vehicle's ride height without shortening the end links

attached to its sway bars will position the bars at an angle and introduce an unwanted

preload, compromising handling performance. To avoid this, I picked up a set of

19-408-BL

end links from Maximum Motorsports and installed them with the springs

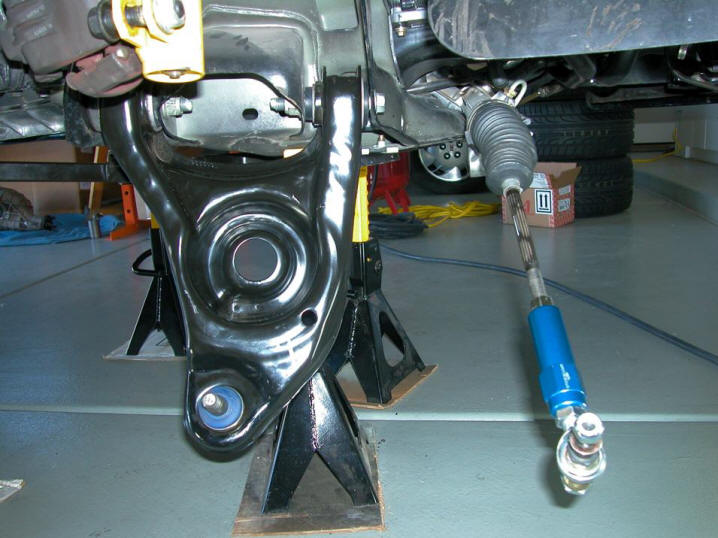

and struts, while I had the front suspension disassembled. Here's a shot of the passenger

side front with the OEM strut, spring, and end link removed:

This is the same corner with the new suspension

components installed.

And here's a photo of the left rear after I had finished swapping out

the shock and spring at that corner. At the time, shorter sway bar end links weren't yet

available for the IRS, so I left the OEM end links in place. Maximum Motorsports

later released some very nice adjustable rear sway bar end links, which made the line-up

for round two of the car's suspension upgrades, but that was years after this photo was

taken.

My initial round of suspension upgrades turned out well, but it had been

less than a barrel of laughs to accomplish, primarily because replacing the OEM springs

with the new ones had been a major PITA. During the swap, I had springs twice jump out

and try to separate my head from my shoulders. Fortunately, the springs had been tethered

with safety ropes, which stopped their progress short each time.

Since then, I've learned quite a few new tricks, and if I knew then what I know now, that

initial suspension project would certainly have gone much more quickly and enjoyably. In fact,

I've completely removed and reinstalled both the front and rear suspensions since then - more

than once - with far less drama. Regardless, I recorded some detailed notes during Taz's 2002

round of suspension upgrades, which may be of interest to some. The link below will take you

to a copy of those notes.

2002 suspension

upgrade notes (PDF)

Suspension Upgrades, Round 2

In 2005, I developed a distinct fondness for open track events,

so I decided to further sharpen the Cobra's handling dynamics, this time with a

stronger emphasis on track performance. I wasn't shooting for the kind of

dedicated racecar dynamics that would brutalize me on bombed out public streets,

just a few meaningful tweaks that would enable me to push the envelope a little

harder when out on the road course. By the end of 2006, after accumulating

various new components over an 18-month period, I finally had all the parts I needed,

so I reserved some time to install them, along

with all the drivetrain goodies I had also been collecting. Due to my limited

free time, installation of all the new parts ran from the beginning of December,

2006 until mid-February, 2007. The poor Cobra was perched on jack stands the entire

time, but when he finally came back down off the stands, Taz had been once again

transformed.

NOTE: For those interested

in a few suspension tuning guidelines, as well as some general technical information

about suspensions, I have added a Handling Tweaks section to this site's

Tech Docs

page.

This round of suspension work included installing fresh

Maximum Motorsports

sway bar end links at both ends of the car (adjustable links in the rear) and swapping out all the

remaining rubber chassis and suspension bushings with poly replacements, except for

the front control arms (more about those below). In the following photo, you can see one of the OEM bushings

being pressed out of the right rear LCA.

NOTE:

For those seeking a surefire solution to the IRS Cobra's

wheel hop during hard launches, I have published the elusive SILVER BULLET

HERE on the Tech

Docs page of this site . You owe it to yourself to give it a read if wheel hop

is an issue for you.

And this photo shows Taz's left rear UCA ready to be

reinstalled on the car after its bushing upgrade had been completed.

TECH TIP: When

installing polyurethane suspension bushings, create a lubricating paste consisting of

25% Permatex

Anti-Seize

and 75% of the synthetic grease supplied with your bushings. Then, apply this paste inside each bushing and

around the outside of its metal crush tube prior to installation. This will provide you with long-lasting

lubrication and a noise-free installation. Do NOT apply this paste to the insides of your bushing shells or

around the outer circumferences of your bushings. Poly bushings weren't designed to rotate within

their shells, and inducing them to do so will shorten their service lives.

Each bushing should rotate around its crush tube. That is the only articulation

you want or need for a proper installation.

Although every "soft part" is considered a wear

item, a good set of properly installed poly bushings will give you many years of

silent, trouble-free service. All of my own poly bushings are still like new and

perfectly quiet after several years of hard use.

Let's take a moment to consider the available suspension bushing options. As with everything else

automotive, one's bushing choices involve tradeoffs. Invariably, the level of

NVH (Noise-Vibration-Harshness) within the cabin will increase with bushing stiffness.

That's just how it is, and only an imbecile would attempt to convince you

otherwise. Rubber bushings, being the most compliant, will

transmit the least NVH, and metal bushings, a.k.a. hard mounts, will transmit the

most, with the NVH transmissions of other materials, such as polyurethane and

Delrin, lying at various points between those two extremes.

Ford OEM bushings are rubber because

Ford places a premium on reducing NVH in order to give its vehicles the broadest market

appeal. However, maximizing isolation exacts certain performance penalties, so

many enthusiasts replace their soft rubber OEM bushings with less compliant

materials to improve handling and responsiveness, reduce wheel hop, etc. There is no

universally perfect formula with respect to bushing upgrades. Some individuals are willing to trade away a great deal more

isolation than others for the sake of performance gains. Consequently, the

material you choose may be unacceptable to me, and vice versa. We are all

individuals, and we all draw different lines in the sand.

I personally like using polyurethane

bushings at suspension points where I want to retain some compliance to keep NVH

in check, yet improve responsiveness beyond that provided by OEM rubber. For a

primarily street-driven car, properly installed poly bushings

will firm up a vehicle's handling very nicely without a lot of objectionable side

effects. With respect to durability and long-term performance, I have never had

any complaint along those lines with the poly bushings on any of my cars. As for

the Cobra, the polyurethane bushings I installed on Taz in 2006/2007 are still like new,

and having been properly greased during installation, they are still perfectly quiet

without the benefit of any periodic lubrication. Just as importantly, they

have vastly improved the car's handling and responsiveness without introducing objectionable

levels of noise or harshness, so I couldn't be happier.

NOTE:

If you're unsure about what bushings might best suit your particular

needs and would like to read more about the pros and cons of each type of material, look

HERE for a copy of the most unbiased and objective

presentation of the full spectrum of bushing alternatives that I have ever found in one place.

I don't agree with everything stated in the comparison, but I consider it a rational enough

presentation to reproduce here. I lifted the text from another website. That site caters primarily

to the import crowd, which often appears to be more open-minded toward all sorts of upgrades than

muscle car devotees tend to be. Most import drivers also share my preference for prioritizing

handling over sheer grunt, which I suppose makes me a muscle-car outcast, but I happen to

believe there's much more to driving than going fast in a straight line.

Editorial Comment:

Poly typically provides the best

handling/isolation balance for my own suspension needs, but as they say, your mileage may vary.

By all means, use whatever material you think will best

suit your purposes, but bear in mind that what's good for a racecar isn't necessarily good

for a street car. Don't come around here crying if you're unhappy with the way your suspension

project turns out if you end up creating a rolling punishment box for yourself

and your passengers. After all, why the hell do you think the manufacturer put

bushings on the car in the first place? Go overboard with your bushing choices

and you'll very likely end up like this poor bastard:

"... now it just feels and

sounds like the whole rear of the car wants to fall off. It seems small bumps or

dips in the

road are the worst. It sounds like the rear shocks have gone out? I could be

mistaken but I understood these cars to ride pretty well after lowering. Any

help? ... I mean, highway driving is good, but for instance in my neighborhood, the

roads suck but I take them at like 10mph, and it still seems I hear and feel every

little bump in the rear."

I didn't invent that comment. I

lifted it off one of the Internet forums. Those are the words of a real

world owner who made the mistake of installing suspension bushings better suited

for a track car on his street-driven IRS Cobra. Here's a comment from another

"satisfied customer" after making a poor bushing choice for his Cobra:

"... I hear so many noises now

I'm scared my rear end is going to fall apart. ..."

Use your head, instead of your hormones,

when selecting bushings. Is this what you want for your own car?

Someone once observed that, "Success

comes from good decisions. Good decisions come from experience. Experience comes

from bad decisions." That observation applies to automotive tinkering, as well

as just about every other aspect of life. But, hey, go for it all you tough guys!

Prove you know more about suspensions and drivelines than automotive engineers

and enthusiasts with decades of firsthand experience. After you turn your cars into

rattle traps and rolling torture chambers, you can just chalk it up as a

"growing experience."

While we're kicking around the topic of good and bad

decisions ... Have another look at the photo above of that IRS upper control arm.

That's a fairly spindly metal casting. Furthermore, it's cast iron, which is a VERY

brittle material. So, just exactly how is it a good idea to drill and tap relatively

LARGE holes in this part, at highly stressed locations, for the purpose of installing

zerk fittings to enable lubrication of its bushings? The correct answer is that it is

NOT a good idea. The engineers didn't put any more material in that control arm than

they considered necessary for the part to do its job.

One last thought. If you're determined to install

Delrin control arm bushings despite my admonishment, be advised that Delrin is

hygroscopic, i.e. it absorbs water. When it does, it swells, resulting in your

smoothly rotating bushings locking up. If that happens, your suspension components

can literally rip themselves apart. Whenever I make a statement like this, I like to

provide some evidence to back it up, so here are a couple of photos of seized Delrin

bushings for your consideration.

With regard to Taz's front control arms, I decided to swap out the factory arms in their

entirety for a pair of Ford Racing

control arms equipped with rubber bushings 50% stiffer than those in the stock arms and designed with

revised balljoint mounting locations that slightly extended the car's wheelbase for improved handling.

After due deliberation regarding the car's primary mission in life (99% recreational driving on public

roads), as well as past personal experience and reports from reliable sources about the NVH increases

resulting from the installation of various aftermarket front LCA bushing materials, I concluded that the

durometer of the bushings in the Ford Racing control arms was where I wanted to be with respect to

the car's front end ride/handling tradeoff. As always, your mileage - and tolerance - may vary, but I've

been very happy with my choice, which is all that counts around here.

Before installing the Ford Racing control arms on the car,

however, I did replace their preinstalled balljoints with double-height

Steeda

X2

balljoints, which are detailed on this site's Steering

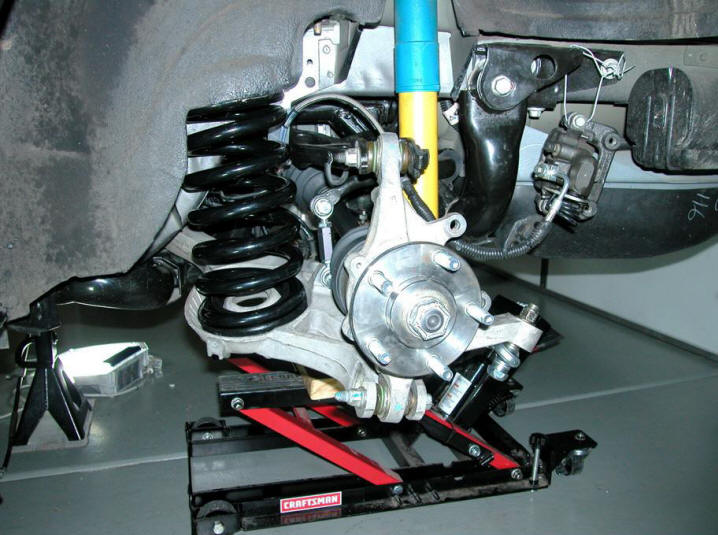

System page. Below is a shot of the right front control arm during

installation, after having been fitted with an X2 balljoint.

And here's a shot of the entire front suspension ready for the wheels

and tires - after minimizing bumpsteer, of course. Details regarding the

Steeda bumpsteer

kit that you see in these photos can be found on this site's

Steering

System page.

TECH TIP: After making

suspension changes, you should always bump steer the car before having it aligned.

Adjusting bumpsteer will alter the car's toe-in, but adjusting toe will not

affect its bumpsteer.

Another aspect of the Cobra's Round Two suspension upgrades focused on its springs. During

my first visit to the road course at Firebird

Raceway, I quickly realized that my trusty H&R Sport Springs, while very nice on the street,

just hadn't been designed for track duty. I needed different springs, and trading away a little ride quality

for improved handling capability was a compromise I was now willing to make, because I had become hooked on the

road course. After searching long and hard, I settled on a set of Engineered Performance #85245

springs. These were being substituted for the Kenny

Brown Performance springs, which were no longer available. The EP springs were manufactured to

the same specs, by the same supplier that had made the Club Sport springs for Kenny Brown. They even

carried the same part number and came packed in identical cartons. They were Kenny Brown springs in every

respect but name, so I bought a set.

The biggest attraction of these springs for me was that, unlike all the other available aftermarket spring sets,

the EP/KBP front springs were constructed with lower rates than the rears (720 lb/in front,

825 lb/in rear). Why is this arrangement preferable for IRS Cobra owners concerned with handling? Because it helps

to reduce push (understeer) by permitting a little more roll at the front compared to the rear, which improves

turn-in. And heaven knows the SN95 chassis can always benefit from a little less push.

Considering this is a longstanding and widely understood suspension tweak, why haven't other

automotive spring companies followed suit? Liability concerns would be my guess. This is undoubtedly the same

reason Ford suspension engineers dialed in so much push to begin with. What? You thought the Ford

boys were just inept? Think again. Endowing a vehicle with a healthy dose of understeer makes it safer for the

"average" (read "incompetent") American driver. In other words, our personal conveyances, just like most everything

else in our lives, have been reduced to the least common denominator, i.e. dumbed down for the masses. Reducing

its push would have made the SN95 platform a much better handler at the risk of making it more dangerous in the

hands of the Great Unwashed. Can't have that, so to avoid potential litigation by those among us who expect to be

protected from their own ineptitude (damned near all of us these days), manufacturers have opted to engineer and

deliver "safer" cars with intentionally hobbled handling dynamics.

This, of course, leaves automotive enthusiasts and malcontents, such as myself, to track down and

apply their own remediation. As far as reversing the front/rear spring bias is concerned, the more adventurous among

us might experiment with creating their own unique spring sets by cannibalizing parts from a couple different commercially

available kits, selecting the front springs from one and the rears from another. The rest of us are more or less left with

either the Kenny Brown springs or coilovers. (Yes, their reversed spring rates account for the majority of the

handling improvement attributed to coilover conversions on IRS Cobras. I'll bet you didn't know that.)

After driving on my Kenny Brown/Engineered Performance springs around the same road course where I

had run the H&R Sport Springs with the same car, I can tell you that the handling improvement at or near the limit

is huge. Turn-in is vastly improved, and the helm more faithfully tracks driver input. Additionally, because of

the linear rates of the new springs, abrupt throttle changes and extreme braking upset the chassis far less than they did

when I was running the H&R springs with their progressive-rate front coils. Although this spring swap was accompanied

by numerous other suspension tweaks, the handling contribution provided by the new springs remained distinct.

Editorial Comment:

If you're not prepared to live with some increased bump harshness, don't install performance

springs - either conventional or coilover - on your car. Yes, there are nimrods running around on crack or acid who will tell

you their cars actually ride better, or at least as well, after being fitted with stiffer suspensions, but that's completely

delusional. They don't. They can't. The simple truth is that if you manage to get everything right, your car will HANDLE better

with performance springs, but it will NOT ride better! H&R and a few of the other spring companies attempt to mitigate the

increased harshness of stiffer springs somewhat with progressive rates at one or both ends, and they have been reasonably

successful in that regard, but progressive springs are less predictable near the limit than linear springs.

Be realistic. Expect a ride/handling trade-off to accompany every performance-oriented

suspension upgrade you perform. Although Taz now handles like he's on rails, he also rides much more like it, as well. His '06 - '07

suspension upgrades have put his ride harshness close to my personal tolerance limit when traversing some of the bombed out streets

in my town. I don't even want to think about how brutal the ride would be if I had opted for even less forgiving bushings than

poly. No thanks. Sure, the harshness of a very stiff suspension does subside at higher velocities. For example, at 80 MPH and above,

Taz's ride motions drop into a sweet spot where this suspension setup feels perfect, but it's difficult to achieve those speeds around

town and retain one's driving privileges.

Except perhaps for color, one spring looks pretty much like

another. Still, you can clearly see the massive wire gauge of the rear EP

spring in the photo below. Compare this spring's wire size to the OEM

spring and H&R Sport Spring that are pictured near the top of this page.

In this photo, you can also see

one of the

Max Motorsports MMRSB-94 adjustable sway

bar end links. (I installed the new end links to eliminate the

preload on the rear sway bar that had been introduced by lowering the car.)

After I installed my Kenne Bell twin-screw kit, the H&R Sport Springs had dropped to a

front ride height of just 26.375 inches from the fender lip to the deck (compared to 26.5 inches prior to my addition

of the blower kit). Switching to the EP spring set increased the car's front ride height to 27 inches (but dropped

the rear from 27.5" to 27.0") following some transitory initial settling. This remains unchanged after years of hard use.

Taz now displays no visible forward rake, but has more road clearance up front, so I have not experienced any rubbing or

scraping with the EP springs.

NOTE: Bear in mind that

I run tires

an inch taller than stock, so you should deduct approximately 0.5" off the above

ride height measurements for an estimate of what the ride height would be with stock diameter

tires. (Factory stock diameter was 25.67". If you are unsure of the diameter of your

own tires, use the

Tire & Drivetrain Calculators

on this site's Tech Docs page to determine what you

have.)

If you'd like to have annotated copies of Taz's 2006 - 2007

driveline and suspension upgrade installation photos, including the photos you

see above, just right click the link below and select the

"Save Target As ..." or

"Save Link As ..." (Firefox) option from the fly-out menu that

will appear. This is a fairly large file (more than 5MB), so it may take a

minute or so to download, but that's still preferable to the delays you would

otherwise encounter trying to view the file in place via the Internet.

2006 - 2007

driveline & suspension upgrade installation photos (PDF)

Editorial Comment:

What about switching to a coilover setup? Isn't that better than a conventional

spring/damper arrangement? Yes, for a chassis that was designed to accommodate coilovers and has been

adequately reinforced to support them. However, after weighing all the advantages and disadvantages of

changing a New Edge platform to a coilover suspension, I elected to stick with an upgraded rendition

of the factory architecture. Considering the reasonably obvious fact that a coilover suspension would have

been less expensive to produce than the OEM setup, I think Ford also must have concluded that the overall

disadvantages of a coilover arrangement for the SN95 outweighed the advantages. By the same token, many

New Edge Cobra owners have switched to coilovers, and many - although not all - of those folks say they

have been satisfied with their results.

In the final analysis, the call is yours, but fact that the SN95's

strut and shock towers were neither engineered nor constructed to bear the full burden of supporting the car's

weight should be apparent to even the most casual observer. And the addition of braces simply cannot compensate

for the structural inadequacies of those towers. Beyond this drawback, all sleeved coilover kits further compromise

suspension reliability, and the only kits for the SN95 of which I'm aware that do not rely on sleeves are the Kenny

Brown kits, which START at about $2700 and the KW Variant kits, which can set you back up to four grand. This is

CONSIDERABLY more than a pair of comparable struts and your choice of performance springs would run, and you'll

still need to beef up the towers, which will cost another bundle if you're not prepared to tackle the welding

yourself.

Then, there are the issues of ride quality degradation and increased NVH.

These are not speculation. They're tangible and worth considering. Here's what the previous owner of an IRS Cobra

had to say about his former coilover setup:

"I had the best coilover setup and

K-member in my 03 Cobra ... and I would never put coilovers in a street car again. Nor would I install any of that lightweight

front end shit on a street car. IT ALL MAKES WAY TOO MUCH NOISE AND CREAKS!! Plus it bottoms out and never rides like

the factory parts. There's always something that's annoying. It's just not worth it. You will hear from people that

their shit is perfect but they need hearing aids!!! ..."

His words, not mine. But it's your car and your choice, so

do what you want. I'm merely pointing out the downside, because apparently SOMEONE has to represent the voice of reason when it

comes to things like this! Here's another owner's comment for your consideration:

"I recently purchased my 03 cobra, it has [respected brand] coilovers all the

way around. When I first got it, I thought I could tuff out the noise, BUT I CAN'T. They are just obnoxious loud and creaking

and popping constantly. ..."

Some owners claim their coilover conversions aren't noisy. Maybe that's true, maybe

not. Regardless, the way your car turns out will be a crapshoot. Furthermore, switching to coilovers will require running

quite a bit of negative camber to address interference issues. Enough to result in uneven and accelerated tire wear. As I said,

the SN95 platform wasn't designed with coilovers in mind.

IRS Subframe Bolts

To expedite assembly, the Ford factory used 12mm, rather than the correct

14mm, bolts to secure the front of the IRS subframes to the chassis of most Cobras. (FYI, 9/16"

bolts are NOT the correct size, either. Those are close to the right size, but a

little too large, so they generally require a BFH to force them in - or out. All fasteners on the

car are metric.) When folks began complaining about their IRS cradles shifting around because of

the slop created by the small bolts,

Maximum Motorsports made the proper 14mm bolts and nuts available to remedy the problem.

I swapped out my 12mm OEM bolts for the MM 14's while reinstalling the IRS cradle, after

completing the 2006 - 2007 IRS upgrades. The

14mm hardware

is shown on the left in the photo below. A pair of

MM low profile rear IRS

subframe bolts are depicted at the right.

Even though the low profile bolts shown above are

marketed for individuals who want to run tires wide enough to encounter

interference issues with the stock bolts, and Taz's 275-width rear tires were

nowhere near wide enough

to present a problem, I installed a pair of the low profile bolts

anyway. A stock rear IRS bolt can be seen in one of the Suspension

Upgrades, Round 2 photos farther up this page, because the low-profile bolts

hadn't yet arrived from Max Motorsports when I shot that photo. However, they showed

up shortly after that shot was taken, just in time for me to get them on the car before

reinstalling the wheels and tires.

Poly Motor Mounts

After several thousand miles of service above and beyond the

call of duty, the rubber OEM motor mounts cashed in their chips.

They simply hadn't been designed to handle either the enhanced torque of the

supercharged engine or the extreme lateral g-forces encountered during the car's

autocross and road course outings. The untimely demise of the motor mounts was

accompanied by a great deal of banging-clanging commotion under hard acceleration

and a rise in overall chassis impact harshness when driving over broken road

surfaces. Even worse, the unwanted engine movement would eventually result in

driveline damage. The mounts had to be replaced.

Realizing that installing a fresh set of OEM parts would

eventually result in another occurrence of the same situation, I researched my alternatives.

Initially, I anticipated that a set of Terminator motor mounts would provide

a suitable upgrade, but I then discovered many complaints of broken mounts among

Terminator owners. Consequently, I discarded those from further consideration

and focused my investigation entirely on the various polyurethane offerings. Solid mounts weren't

contenders, because they're far too brutal to suit me.

During my research, I discovered that not all poly motor mounts

are created equal. It seems the Energy Suspension

motor mounts, which are based on the company's patented Hyper-Flex

formulation, are much more compliant than the other brands. People who had

installed the Energy Suspension mounts were invariably pleased, while

those who had installed mounts from other manufacturers generally complained

about the increased levels of NVH that had accompanied their installation. Based

on the fairly consistent owner feedback, I decided to

try the Energy Suspension

mounts, which I purchased and installed during the summer of 2009.

My hat goes off to those who have managed to install fresh motor mounts on SN95 Mustangs without first dropping their K-members,

at least those with factory K-members. I

briefly considered trying this myself, but thought better of it as soon as I

began the work. Having by this time previously dropped Taz's K-member, I realized

that path offered the least resistance, so that's what I did. This turned out to

be the right call, and the swap went so uneventfully that I didn't

even bother to shoot any photos during the process. However, I later snapped

a shot, reproduced below, of the old OEM mounts after their removal.

Aside from the distortion of their rubber isolation blocks,

there's very little visible deterioration in the old mounts - not a single crack or

split to be seen anywhere on the exposed rubber surfaces - but they were definitely shot. Before

removing each from the engine block, I grabbed it and wiggled it around. Each

moved far more easily than it should have.

Additionally, both mounts - particularly the right one - were severely compressed,

which had put the oil pan perilously close to the factory K-member brace.

Even though the swap was extremely straightforward, I recorded

detailed notes that include each step

of the procedure necessary to drop the K. If you're among those who may be a little unsure

or apprehensive about

dropping your car's cross-member in order to gain access to parts obscured behind it, check

out the Adobe PDF document linked below, and you'll see how easy it

really is. Although some of the details in these notes are specific to my car

and its particular parts, the general procedure should be adaptable to any SN95.

Dropping the K-member to

Replace the Motor Mounts (PDF)

As for the Energy Suspension mounts, they have earned my

enthusiastic and unqualified endorsement. Although I must concede that they're less compliant

than a fresh set of OEM mounts would have been, I am experiencing a very acceptable level of

NVH with these, and they should enjoy greatly extended service lives compared to the OEM parts.

As expected, the commotion during hard acceleration has disappeared, indicating that I'm no

longer beating up my driveline. Beyond that, I imagine I'm losing less power to unwanted engine

movement.

Rear Sway Bar

As previously mentioned on this page, permitting a little more

roll at the front of the vehicle compared to the back improves turn-in, reducing

push (understeer). Early in 2012, when my friend Joe informed me that the

Eibach sway bars were

being offered by one of the Internet parts vendors at fairly healthy discounts,

and that Eibach was further sweetening the pot by providing factory

rebates, I found it impossible to pass up such an appealing offer. Even though

Taz's suspension had been well sorted out for years, the car continued to demonstrate

some residual understeer. Although I feared this was an incurable SN95

affliction, I hoped a stouter rear bar might alleviate the

lingering push, if only by a little.

I wasn't expecting an earth-shattering improvement, since I had

read very few glowing reports regarding the benefits afforded by aftermarket sway

bars. But the majority of Mustang owners, who typically throw parts at

their cars with little understanding of the engineering behind those parts or the

ramifications of installing them, almost always bought and installed complete kits

containing both front and rear - supposedly "matched" - bars. (If one

is good, two must be better, right?) Unfortunately, aftermarket parts suppliers,

who are generally every bit as sensitive to liability exposure as automotive

manufacturers, are likely to calibrate their sway bar kits for a healthy dose

of understeer in order to "protect" the less capable among us from

themselves. I suspected that the installation of these complete kits was the

primary reason why people weren't reporting more impressive results with the

aftermarket bars, but I was uncertain as to what extent the inherent push of a

New Edge Cobra could be reduced by installing only a stiffer rear bar and leaving

the front end well enough alone. Nevertheless, given the bargain basement pricing,

I intended to find out, so I bought a rear bar kit, which included fresh

urethane bushings in addition to the bar itself.

Several sources, including the Ford shop manual, stated that

the prescribed method for replacing the rear sway bar of an IRS-equipped Cobra was to

partially drop the rear suspension cradle. Recalling from past experience the

amount of work that entailed, and not anticipating any sort of miraculous

transformation, I was in no particular hurry to install the bar, so it sat in my

garage for a couple months. However, I immediately realized after taking a good

look at everything back there while the car was on stands for an oil change that

access to the bar and its brackets could be gained by dropping the fuel tank,

instead of the IRS cradle. I was already shopping for a tank upgrade, so I

decided to perform the two installations together after I'd procured a suitable

tank. This I did, and as the photos below clearly demonstrate, the bar and

brackets are readily accessible with the fuel tank out of the way.

During the installation, I was able

to select the bar's back (stiffer) end link attachment holes. However, I'm

fairly certain that I would have been forced to use the front holes if I had

been running stock halfshafts. As you can see in the photo below, although

perfectly vertical with the suspension loaded, the end links swing very close to

my DSS Level-5 axle bars at full droop. I suspect I'd have encountered

interference problems there with the OEM axles, because they are somewhat larger

in diameter than the L-5's. (See Taz's Drivetrain

page for a comparison photo showing the two axles side by side.)

Of course, the entire point of this exercise was to reduce

understeer, so the question foremost on my mind was how effective the

installation of this bar had been with regard to that objective.

My first drive after the upgrade unequivocally answered this question.

What a difference! Taz's turn-in was spot-on. He went exactly

where I pointed him. However, I was amused to note that I had become so accustomed to

automatically compensating for the residual understeer that still remained after all the

earlier suspension and steering tweaks that I now found myself consistently overcorrecting

the carís path. It was apparent that I'd to need to acquaint myself with Taz's handling behavior

all over again, but that would be fun and a small price to pay for achieving the absence of

understeer.

As always, your mileage may vary. This bar provided precisely the correction to Taz's

turn-in that was required to completely eliminate all his residual push, but it may not benefit your car

as greatly due to other chassis, suspension, and steering differences. Nevertheless, installing this

bar - just the back one - will go a long way toward reducing any IRS-equipped Cobra's

understeer. Even though Joe's Terminator is set up somewhat differently from Taz, and even though he

was forced to use the bar's forward end link attachment points, he too observed a

remarkable improvement in his Cobra's turn-in when he installed his Eibach rear bar. Two for

two, while perhaps not statistically significant, is a pretty good batting average, and you can take

that to the ball park.

![]()